Even a “correct” DXF file can derail CNC production due to subtle issues like micro-gaps in contours, duplicate lines, incompatible units, or tool radius mismatches. This guide provides a systematic methodology to ensure DXF files are truly cut-ready, minimizing errors and optimizing shop floor efficiency. By following a structured validation process, engineers can prevent costly reworks and material waste.

What “Cut-Ready” Means for DXF in Real CNC Shops

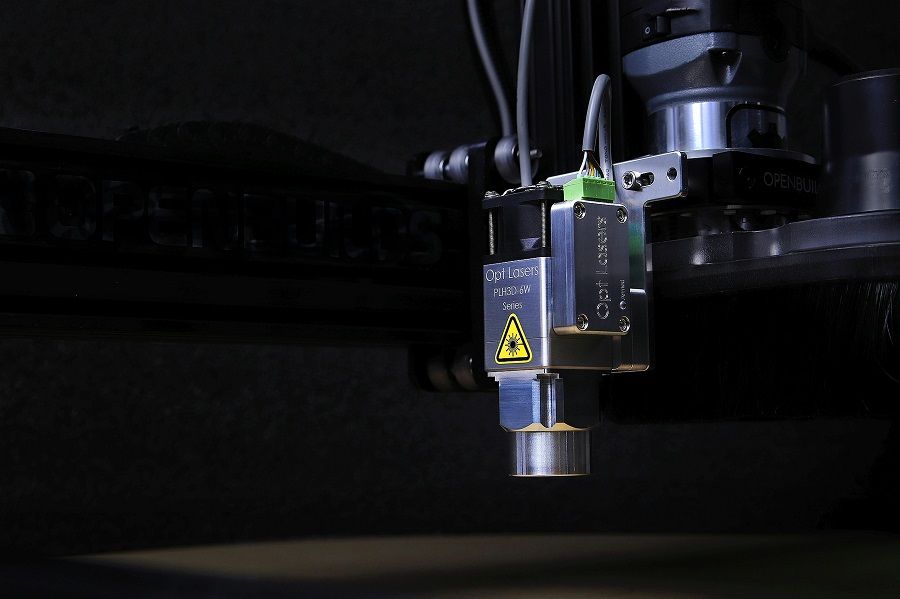

A cut-ready DXF file is one that a CNC machine—whether plasma, laser, or waterjet—can process without errors or interruptions. This requires meeting specific criteria tailored to the machine, material, and cutting process:

- Closed Contours: All paths must form continuous, closed loops. Gaps, even microscopic ones, can cause the machine to skip sections or produce incomplete cuts.

- No Self-Intersections: Lines or curves that cross themselves create ambiguous toolpaths, potentially stalling the machine or ruining the part.

- Unified Coordinate System and Units: The file must use a single coordinate system (e.g., Cartesian) and consistent units (mm or inches) to prevent scaling errors.

- Tolerances: Geometry must align with machining tolerances, typically 0.01–0.1 mm, depending on the machine’s precision and material properties.

- Minimum Feature Size: Features like holes or corners must exceed the tool’s minimum width or radius (e.g., a 1 mm laser beam requires features larger than 1 mm).

These criteria ensure the DXF translates seamlessly from design to production, reducing downtime and defective outputs.

Pre-Flight Verification: A Step-by-Step Workflow

The pre-flight verification process systematically prepares a DXF file for CNC cutting by identifying and resolving issues before production begins. Here’s a detailed workflow:

- Import and Unit Normalization:

- Open the DXF in a CAD tool like AutoCAD, Fusion 360, or QCAD.

- Confirm and standardize units (mm or inches) to match the CNC machine’s settings. Mismatched units can result in parts being scaled incorrectly.

- Align the drawing’s origin point with the machine’s coordinate system for accurate positioning.

- Smoothing and Simplification:

- Smooth curves to remove jagged edges or excessive nodes, which can cause erratic tool movement or slow processing.

- Simplify complex splines into arcs or polylines, as some CNC controllers struggle with high-order curves.

- Automated Detection of Gaps and Duplicates:

- Use CAD tools or utilities (e.g., Inkscape, QCAD) to identify micro-gaps or overlapping lines. Gaps as small as 0.01 mm can disrupt cutting.

- Eliminate duplicate lines to prevent redundant cuts, which waste time and may damage the material.

- Minimum Radius and Kerf Check:

- Ensure all features (e.g., holes, corners) meet the tool’s minimum radius requirement. For instance, a 0.5 mm plasma cutter cannot accurately cut a 0.3 mm radius.

- Apply kerf compensation (accounting for material removed by the cutting process) using CAM software like SheetCAM or Fusion 360.

- Export to a Control DXF:

- Save a clean DXF file after corrections, using a compatible format like AutoCAD R12 for older CNC controllers.

- Verify the file in a lightweight DXF viewer (e.g., DXFView, eDrawings) to ensure no artifacts were introduced during export.

This DXF validation workflow ensures the file is free of errors and optimized for the CNC machine.

Tools for Each Stage of the Process

Various software tools support the DXF preparation process, each serving a specific role. Here’s an overview without ranking or “top” lists:

- CAD Software (e.g., AutoCAD, Fusion 360, LibreCAD, QCAD): Used for creating and editing DXF files. These tools enable precise geometry adjustments, unit normalization, and contour cleanup. For example, AutoCAD’s “Overkill” command efficiently removes duplicate lines.

- DXF Viewers (e.g., DXFView, eDrawings, DWG TrueView): Lightweight tools for verifying file integrity without full CAD software. They confirm the DXF renders correctly across systems.

- CAM Software and Plugins (e.g., SheetCAM, Fusion 360 CAM, NCPlot): These generate toolpaths, apply kerf compensation, and simulate cutting to identify issues like unreachable areas.

- Cleanup Utilities (e.g., Inkscape, DXF2Gcode): Specialized tools for removing duplicates, stitching gaps, or converting text to curves. Inkscape’s “Path > Simplify” reduces node counts in complex designs.

The choice of tool depends on the project, machine, and engineer’s expertise, ensuring flexibility in the DXF pre-flight check process.

Common Issues and How to Fix Them

DXF files often contain subtle errors that disrupt CNC cutting. Below are common problems and their solutions:

- Micro-Gaps: Tiny breaks in contours can cause the machine to skip sections. Zoom in using CAD tools or use automated “Close Contour” functions to fix gaps.

- Open Splines: Unconnected splines confuse CNC controllers. Convert splines to polylines or arcs and ensure all paths are closed.

- Multiple Layers or Colors: Some machines misinterpret layers or colors as separate toolpaths. Flatten the DXF to a single layer with uniform line properties.

- Duplicate Lines: Overlapping lines lead to redundant cuts. Use tools like AutoCAD’s “Overkill” or QCAD’s “Remove Duplicates” to eliminate them.

- Thin “Bridges”: Narrow sections (e.g., <0.5 mm) may not survive cutting due to heat or stress. Widen these areas or add tabs to secure parts.

- Text and Fonts: Text objects can cause errors, as CNC machines don’t process them. Convert all text to curves or paths before exporting.

Addressing these during pre-flight verification prevents production delays and ensures CNC-ready vectors.

Quality Control Before Production

A final quality check ensures the DXF is ready for the shop floor:

- Local Simulation (“Dry Run”): Use CAM software to simulate the cutting process, identifying toolpath errors like collisions or unreachable areas without wasting material.

- Test Cut (50×50 mm): Produce a small test piece to verify geometry and cutting accuracy, especially for complex designs or new materials.

- Marking Verification: Confirm that engravings or labels are correctly positioned and scaled, aligning with material properties (e.g., engraving depth for lasers).

- File Naming and Versioning: Use clear file names (e.g., “PartName_v1.2.dxf”) with version numbers to avoid confusion and track changes.

These steps confirm the DXF is production-ready, minimizing errors during cutting.

Engineer’s Checklist for DXF CNC Cut Ready

Below is a printable, one-page checklist to standardize the validation process. It includes 12 actionable items with checkboxes:

DXF CNC Cut Ready Checklist

- Units normalized to match CNC machine (mm/inches).

- All contours closed (no gaps or open paths).

- No self-intersecting lines or curves.

- Single coordinate system used throughout.

- Minimum feature size exceeds tool radius/kerf.

- Duplicate lines removed (e.g., via Overkill).

- Text converted to curves/paths.

- Layers flattened to a single layer.

- Kerf compensation applied (if required).

- File tested in a DXF viewer (e.g., DXFView).

- Simulation/dry run completed in CAM software.

- Test cut (50×50 mm) performed successfully.

File Name: ____________________ Version: _______ Date: ________

This checklist can be printed and used in the workshop for consistent file validation.

Safety and Material/Tool Compatibility

Safety is paramount when preparing DXF files. Ensure the design accounts for the material’s properties (e.g., thickness, heat sensitivity) and the tool’s limitations (e.g., maximum cutting depth). For example, thicker materials may require wider kerf offsets to prevent overheating. Verify that the DXF aligns with the machine’s safety parameters, such as speed or power limits, to avoid equipment damage or operator risk.

A robust DXF CNC Cut Ready methodology reduces production errors, minimizes material waste, and streamlines CNC workflows. By implementing a structured pre-flight process, leveraging appropriate tools, and using a standardized checklist, engineers can ensure files are optimized for cutting. For further learning, explore CNC programming manuals or CAD/CAM software documentation. Adopting these practices enhances efficiency, improves part quality, and reduces costly reworks in the shop.